MARKING OF METALS

Futonics fiber lasers are well-suited for processing a variety of metals due to their absorption properties around infrared wavelengths. Markings are performed accurately and with a high level of detail on both soft metals such as aluminum as well as steel and hard alloys.

- Aluminum

- Stainless steel

- Metal alloys

- Copper

- Brass

- Silver

- Gold

- Coated metals

A wide range of industries use metal marking, especially where products and parts must have traceable features. This includes the electrical and electronics industry, the mechanics and tool manufacturing industry, the airline industry, and the automotive industry.

EXAMPLES OF USES

- Product labeling

- Metal tags

- Serial numbers, product information and codes for traceability

- Logos, text and images

- Functional markings on tools

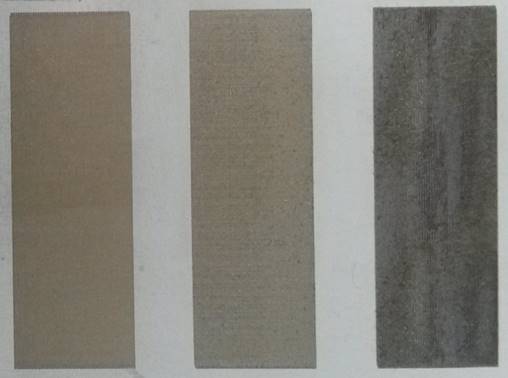

Temper marking of metals such as stainless steel is a process whereby a dark oxide coating is built up with no material removal, offering several advantages over other marking processes. Coloring is directly related to output power.

Here the serial number of the F-TO 175/2000 is engraved on anodized aluminum using an IFL30.

BENEFITS

- Contactless, permanent markings

- No pre- or post-processing is required

- Precise and clean metal processing

- Very fine details are achieved on complex images, logos, codes, and text