CUTTING OF FIBER-REINFORCED PLASTICS

Futonics fiber lasers have the ability to create a highly focused, high-powered beam that cleanly cuts through fiber-reinforced plastics in a variety of complex shapes.

Fiber-reinforced plastics are composite materials whereby a polymer matrix is reinforced with fibers in order to improve the strength and elasticity of the material. The fibers are typically made of glass or carbon, and the polymers can be either thermosetting plastics or thermosoftening plastics, which have the ability to return to a pliable state above a specific temperature without significant permanent chemical changes. Fiber-reinforced plastics are used in industries that make use of lightweight construction including, for example, the automotive, aircraft, construction, military, marine and aerospace sectors.

Traditional machining processes for composite materials involve short lifetimes of the cutting tools, leading to high costs. Laser cutting of fiber-reinforced plastics has recently gained some ground as a wear-free and economical alternative to conventional approaches. However, the inhomogeneous nature of composite materials means that they have different absorption properties, making them difficult to be processed by means of lasers, which generally work best at targeted absorption wavelengths and thus on homogenous surfaces.

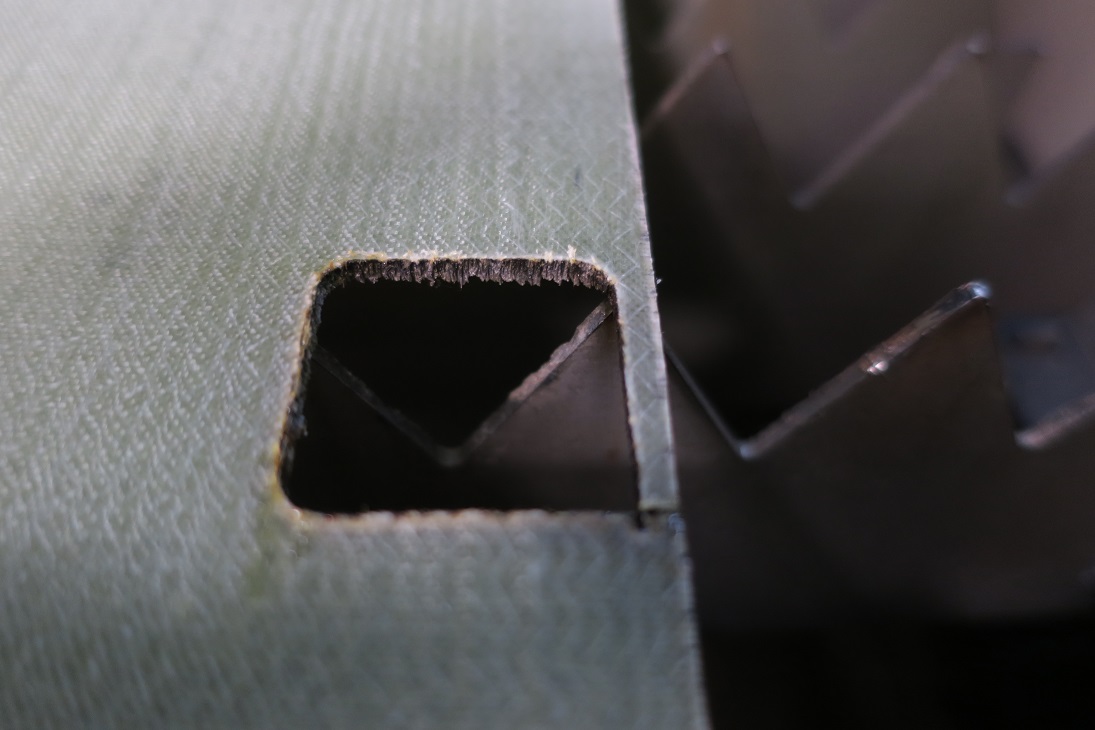

Fiber lasers provided by Futonics cut fiber-reinforced plastics with a high speed and clean cuts.

BENEFITS

- Complex shapes are cut with high precision

- Wear-free cutting of fiber-reinforced plastics

- Economical advantage over conventional machining processes

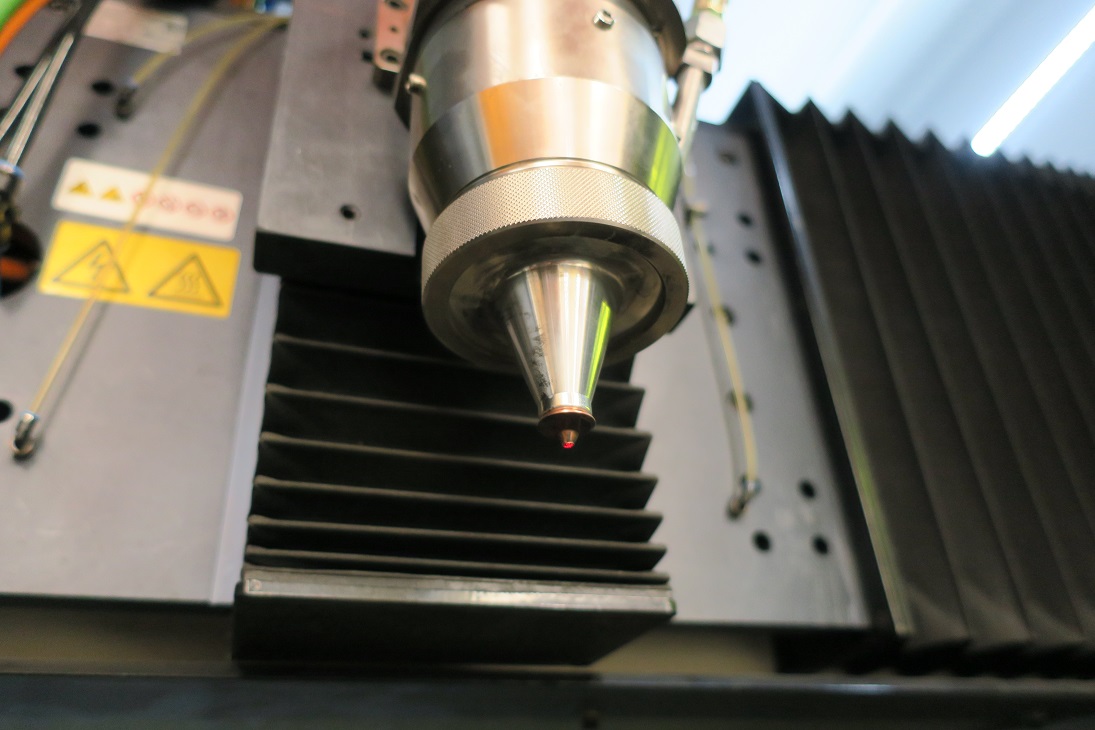

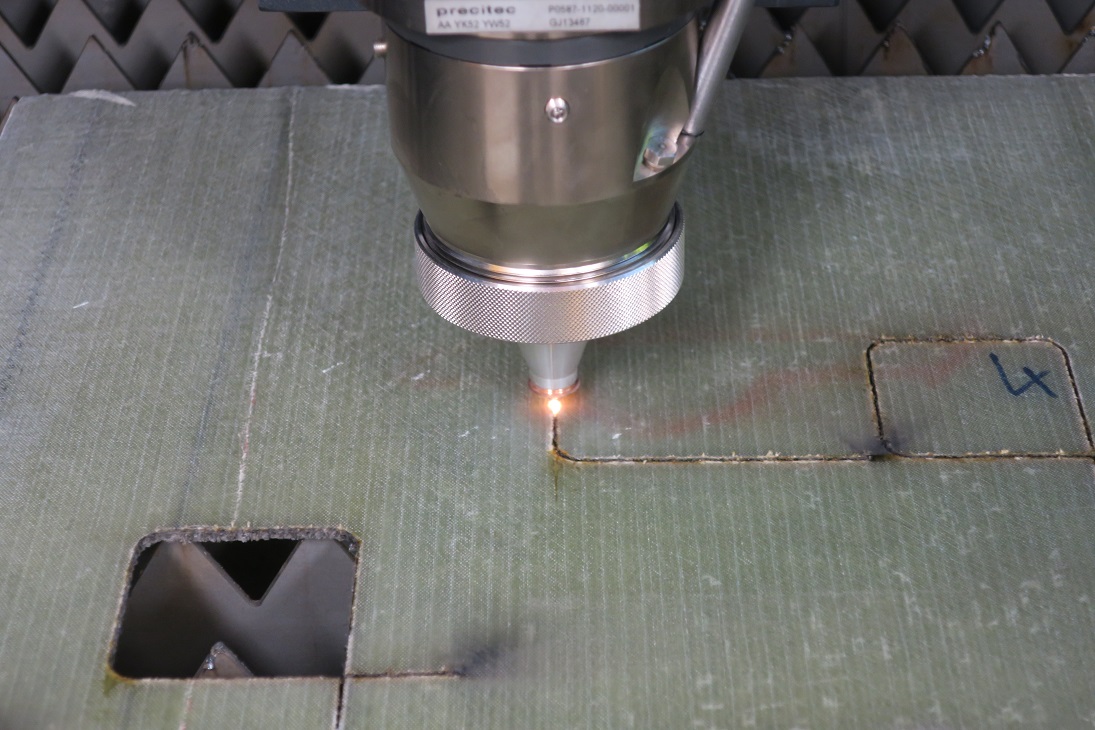

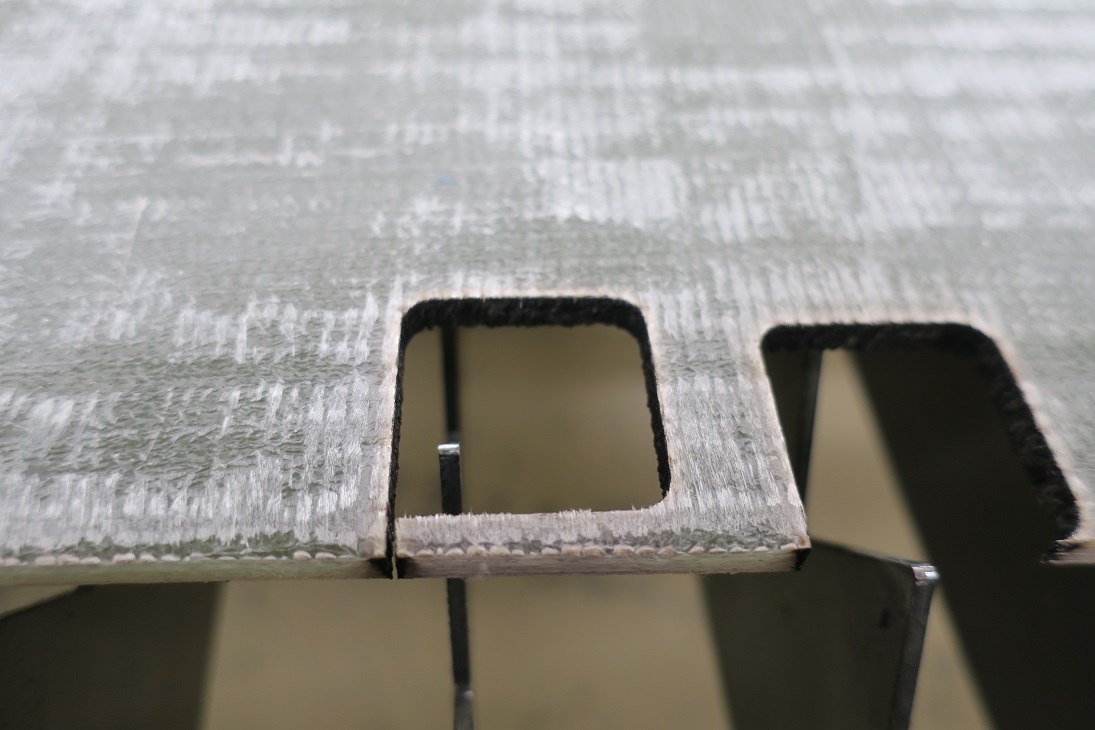

Futonics fiber lasers have been used as the laser source for processing composite materials. Shown below is a collaboration with Durmazlar Makina.

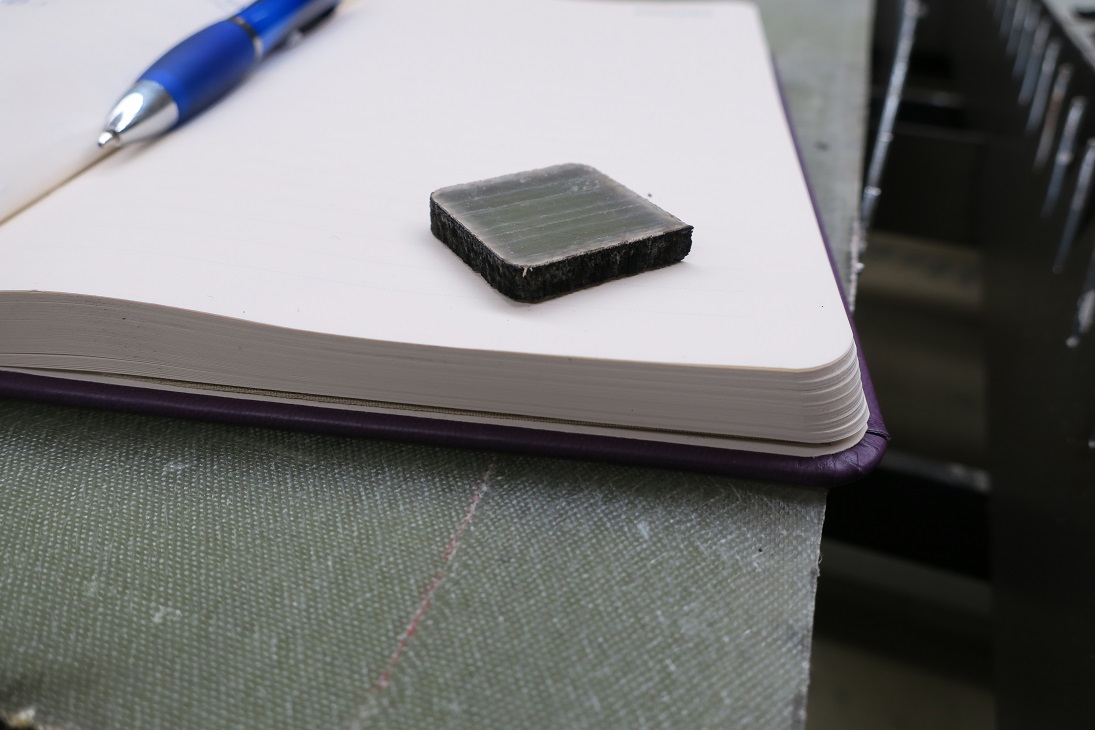

The pictures show the cutting process of E-glass. Other similar materials have been successfully cut by Futonics fiber laser systems.

VIDEO DEMONSTRATIONS