WELDING OF POLYMERS

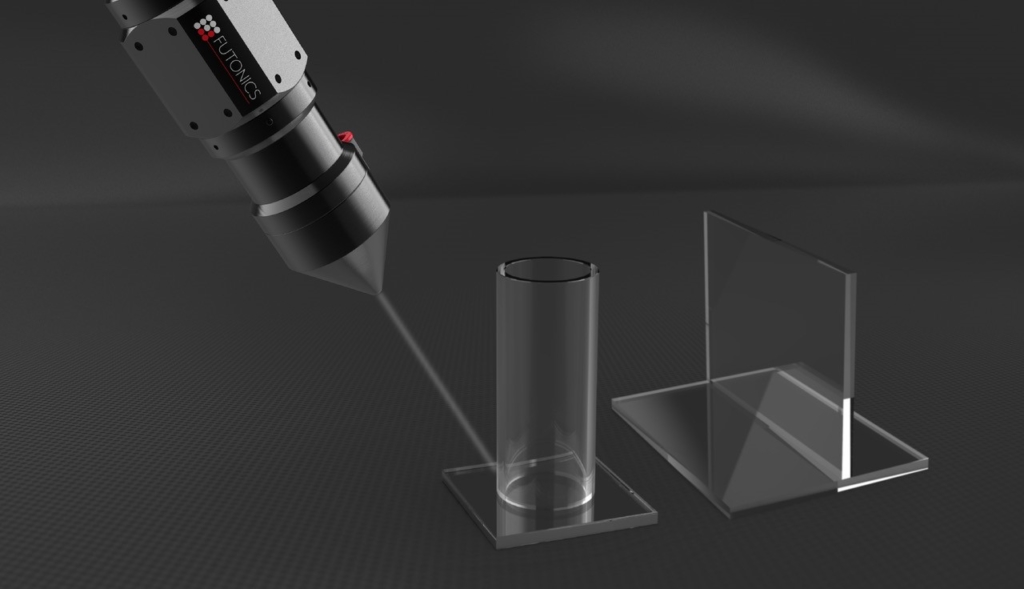

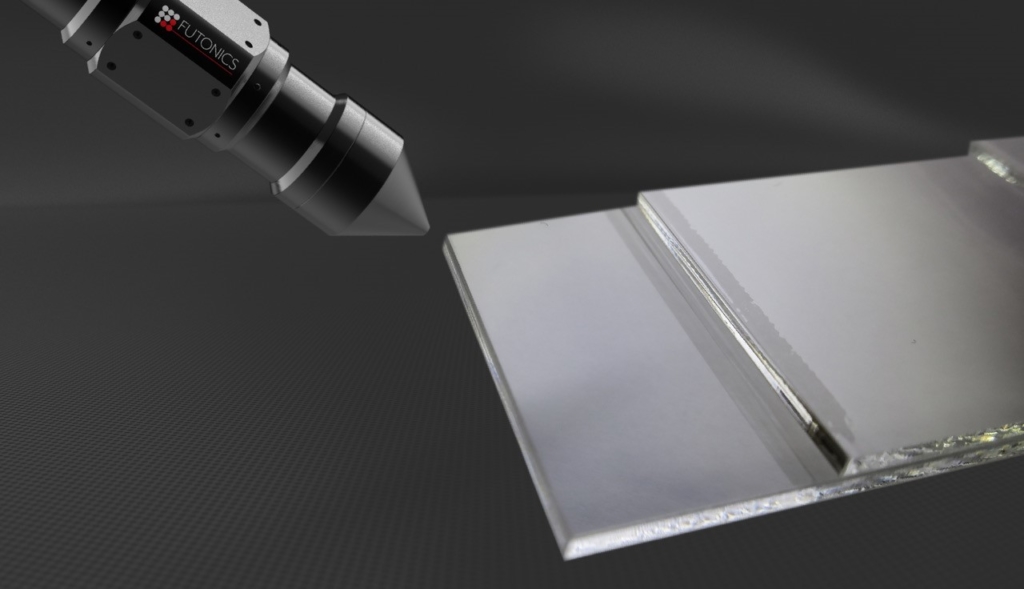

Welding of transparent polymers is possible using the intrinsic absorption of laser light emitted by Futonics laser systems. This patented technology offers high precision and control of the process. Various thermoplastic materials can be used with this method without the need for additives, leading to a more efficient overall process.

Laser welding of plastics is a method that has become more common and accepted in industry applications in the last couple of decades. It has several advantages over traditional methods, which include applying external heat sources, generating heat through mechanical movement, and certain other electromagnetic techniques.

CO2 lasers are used for making joints at high speeds, but the working depth is quite small, limiting their use to plastic films. For welding of thicker non-transparent polymers, Nd:YAG and diode lasers are much more suitable. The working area is very precise and concentrated, creating a seamless joint. Lasers emitting at 2 µm combine the mentioned advantages and are very attractive for transparent polymers. Additionally, 2 µm lasers are nominally eye-safe.

Futonics fiber lasers are ideal for welding a variety of clear and colored thermoplastic materials.

You can find out more about welding polymers using our lasers in the article “Welding of transparent and opaque polymers with single-mode Tm-doped fiber lasers” erfahren.

BENEFITS

- High precision welding that results in accurate joint formation

- No contact between the welding source and plastics

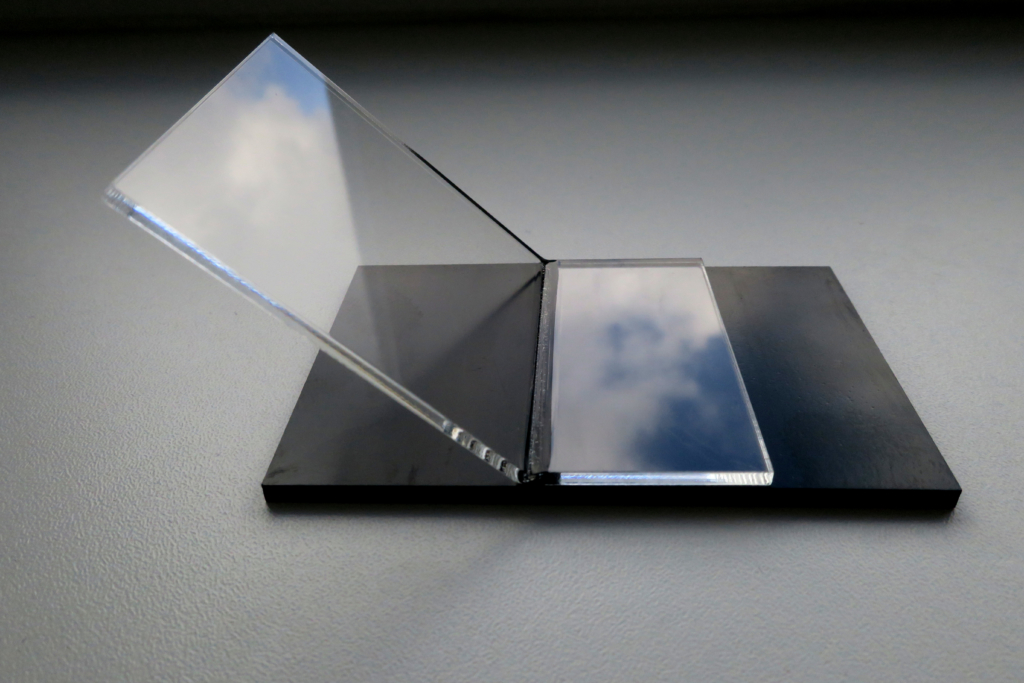

- No marking of the outer surfaces

- No need for additional plastics, implants or pigments at the joints

- No need for additives

- Butt-joints are realized

- Low-energy usage

- Eye-safe compared to other laser-assisted welding operations

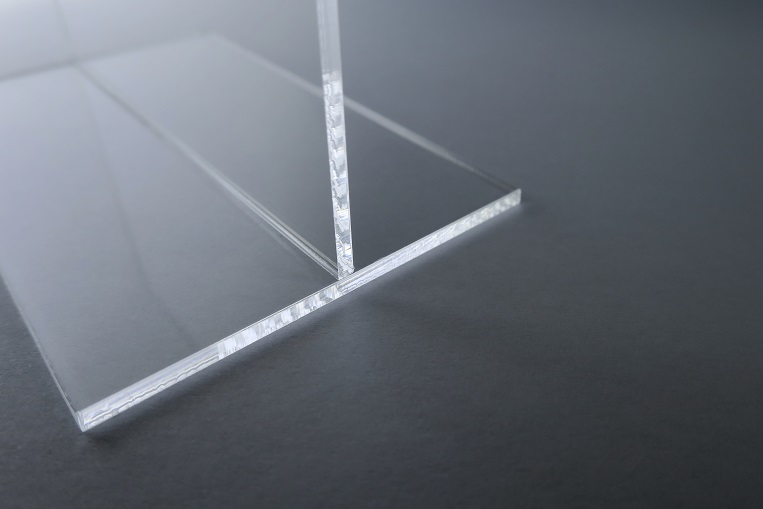

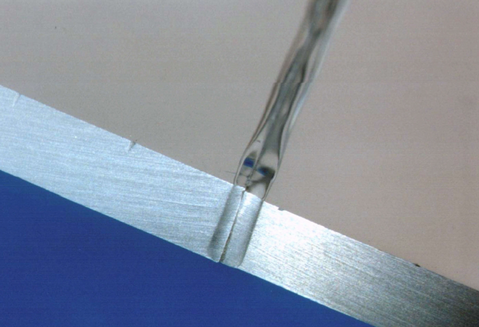

Shown here is a tee-joint welding of PMMA with a Futonics 2 µm Thulium fiber laser.